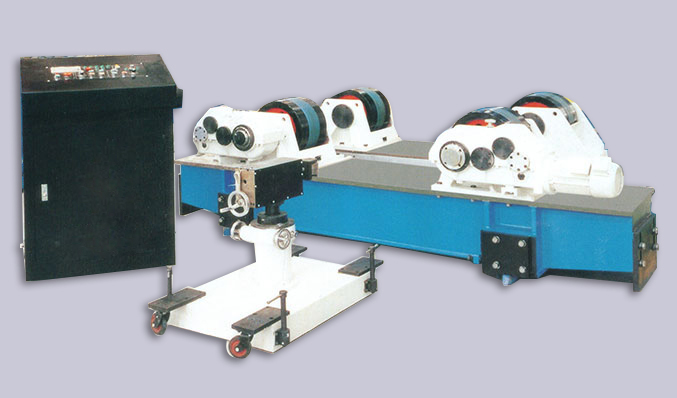

Features:

1. Used for deviation correction of thick-wall and narrow-gap cylinder welding

2. Designed for preventing axial float of workpice: A weldment is in helical motion during rotation to generate axial float, which through rising or lowering of the driven roller, changes the helical angle between the axis of weldment and axis of roller, leading to change in the axial displacement direction of weldment

3. Compact structure, strong capability of deviation correction, anti-floating accuracy ≤±2mm

4. Suitable for strip surfacing and narrow gap welding of high-tonnage weldment with high requirements for accuracy of weld joint position and stability of welding speed

Technical parameters:

| Model |

Max. load (kg) |

Diameter range

of workpiece (mm) |

Roller diameter

and width (mm) |

Linear velocity of roller

(m/h) |

Motor power

(kw) |

Anti

-floating accuracy

(mm) |

Mode of speed control |

| Rubber |

Metal |

| HGFK40 |

40000 |

Φ 600-4200 |

Φ 400× 120 |

2 ×392×80 |

3-60 |

2×1.5 |

≤土 2 |

Variable-frequency

stepless control

or DC pulse width

stepless control |

| HGFK60 |

60000 |

Φ 750-4800 |

Φ 450× 120 |

2 ×442×90 |

3-60 |

2 × 2.2 |

| HGFK100 |

100000 |

Φ 1000-5500 |

Φ 500 × 120 |

2 ×492 ×100 |

3-60 |

2×3 |

| HGFK160 |

160000 |

Φ 1100-6000 |

/ |

Φ 620×220 |

3-60 |

2×4 |

| HGFK250 |

250000 |

Φ 1200-7000 |

/ |

Φ 700×260 |

3-60 |

2×5.5 |

| HGFK400 |

400000 |

Φ 1300-7500 |

/ |

Φ 800×320 |

3-60 |

2×7.5 |

| HGFK650 |

650000 |

Φ 1400-8500 |

/ |

Φ 900×400 |

3-60 |

2×11 |

|