| CONTACT |

|

|

WUXI ZUOSHAN WHEEL FRAME WELDING MANUFACTURING CO.LTD.

Address: Wuxi Xinwu District

Contact: Tang Hualing

Mobile:13182098269

TEL:0510-85361050

FAX:0510-85361095

Http://www.worldthl.com

E-mail:zs@worldthl.com |

|

|

|

|

PRODUCT

HOME » PRODUCT

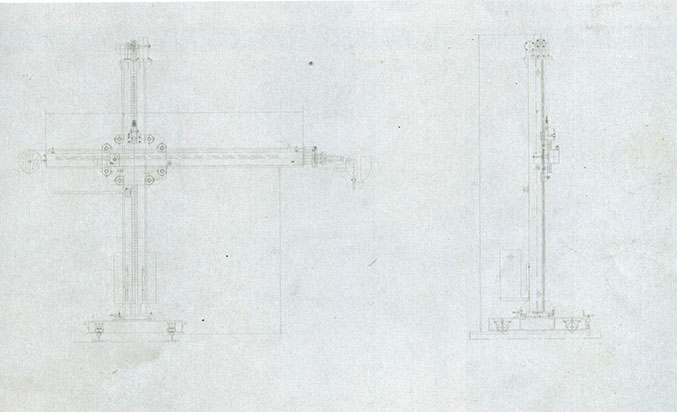

| Automatic welding manipulator | Light-duty automatic manipulator

Main technical parameters:

| Technical parameter/model |

HJ1 ×1 |

HJ2×2 |

HJ3×3 |

HJ4×4 |

| Lifting stroke |

1000 |

2000 |

3000 |

4000 |

| Retracting stroke |

1000 |

2000 |

3000 |

4000 |

| Lifting speed |

1000 |

| Retracting speed |

120-1200 |

| Min. distance between lower edge of cross arm and rail surface |

740 (mobile rotary type), 690 (fixed rotary type) |

| Max. allowable load at front end of cross arm |

80 |

| Column rotation |

Screw locked after manual rotation in place |

| Trolley running |

Screw locked after manual push in place |

| Inner span of trolley rail |

1000 |

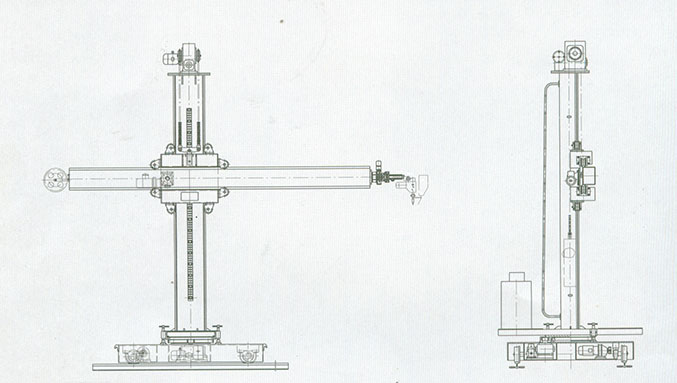

Medium/heavy-duty automatic manipulator

Features:

Automatic manipulators are classified into light-duty type (LHQ), medium-duty type (LHZ), heavy-duty type (LHW) and extra-heavy duty type (HCJ) by load capacity at the front end of cross arm.

Structural types: fixed type, fixed rotary type, mobile rotary type

Sections of cross arm and column are subject to scientific calculation; sag of horizontal extension/extraction of cross arm 2mm/m;

Lifting gear of cross arm is equipped with a fall protector, a ratchet-pawl mechanism, thus safe and reliable;

Cross arm is equipped with a cross-shaped micro-adjusting mechanism at the front end, which can be operated through the remote-control box.

The guide axle is an eccentric axis that can easily eliminate the gap between roller and guide rail;

Column can be rotated manually or electrically; the locking mechanism rotated in place has two types, namely manual type and pneumatic type;

The electrical part consists of an electric control box and remote control box, and is designed with a control interface for connection with positioner and turning roll.

Main technical parameters:

| Technical parameter/model |

HJ4 ×4 |

HJ5×5 |

HJ6×6 |

HJ7×7 |

| Lifting stroke |

4000 |

5000 |

6000 |

7000 |

| Retracting stroke |

4000 |

5000 |

6000 |

7000 |

| Lifting speed |

1000 |

| Retracting speed |

120-1200 |

| Min. distance between lower edge of cross arm and rail surface |

1110(mobile rotary type)/950(fixed rotary type) |

1180(mobile rotary type)/1170(fixed rotary type) |

| Max. allowable load at front end of cross arm |

120 |

200 |

| Column rotation |

Angle |

±180° |

| Speed |

0.36rpm/or manual |

| Trolley running |

1700 |

2500 |

| Inner span of trolley rail |

1730 |

2000 |

2000 |

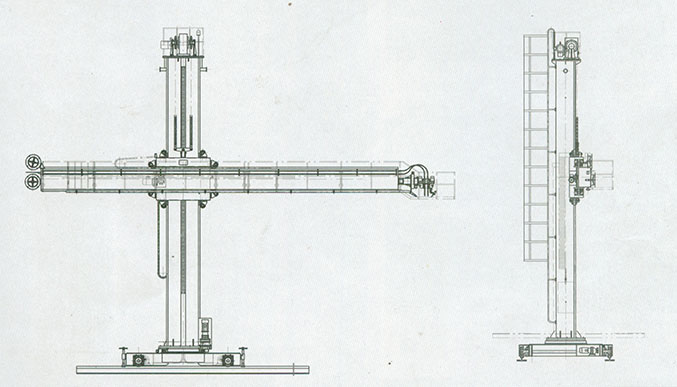

Extra-heavy duty automatic manipulator

Features:

Automatic manipulators are classified into light-duty type (LHQ), medium-duty type (LHZ), heavy-duty type (LHW) and extra-heavy duty type (HCJ) by load capacity at the front end of cross arm.

Structural types: fixed type, fixed rotary type, mobile rotary type

Sections of cross arm and column are subject to scientific calculation; sag of horizontal extension/extraction of cross arm 2mm/m;

Lifting gear of cross arm is equipped with a fall protector, a ratchet-pawl mechanism, thus safe and reliable;

Cross arm is equipped with a cross-shaped micro-adjusting mechanism at the front end, which can be operated through the remote-control box.

The guide axle is an eccentric axis that can easily eliminate the gap between roller and guide rail;

Column can be rotated manually or electrically; the locking mechanism rotated in place has two types, namely manual type and pneumatic type;

The electrical part consists of an electric control box and remote control box, and is designed with a control interface for connection with positioner and turning roll.

Main technical parameters:

| Technical parameter/model |

HJ 5×5 |

HJ 6×6 |

HJ 7×7 |

HJ8×8 |

| Lifting stroke |

5000 |

6000 |

7000 |

8000 |

| Retracting stroke |

5000 |

6000 |

7000 |

8000 |

| Lifting speed |

1650 |

| Retracting speed |

50-1000 |

| Min. distance between lower edge of cross arm and rail surface |

1290(mobile rotary type) |

1210(fixed rotary type) |

| Max. allowable load at front end of cross arm |

600 |

500 |

400 |

| Column rotation |

Angle |

±180° |

| Speed |

0.17rpm/or manual |

| Trolley running |

2000 |

| Inner span of trolley rail |

2500 |

|

|   |

|